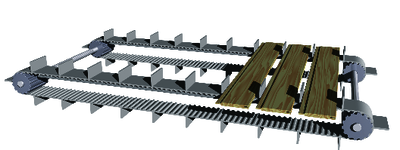

Timing belts with welded-on profiles are suitable for versatile transport purposes as they can be fitted with any profiles in customer-specific numbers and sequences. Welding on the respective profiles ensures a durable connection to the timing belt surface and thus enables individual design of the cam timing belt. Customer-specific profile shapes can also be produced by injection molding or 3D printing. Simply contact us for this.

Standard profiles:

- Standard profiles are produced from an existing tool.

Our profiles are manufactured as polyurethane injection molded parts. There are more than 3000 standard profiles to choose from, which can be subsequently modified by mechanical processing (drilling, milling) depending on the dimensions. For customized designs we need a dimensioned drawing. - Profiles are manufactured from a semi-finished product.

Depending on the quantity required, profiles are cut from prefabricated PUR sheets if necessary. The following plate thicknesses are available: 1.5; 2; 3; 4; 5; 6; 7; 8; 10; 11; 15; 20 mm.

Special profiles:

- Profiles from new tools:

For new design requirements, there are practically no restrictions in the shaping of injection-moulded profiles within the scope of our production possibilities. Tool costs must be taken into account. - Profiles from 3D printing:

3D printing opens up new and individual possibilities for us to manufacture profiles in small quantities in a customer-oriented manner. Please send us your drawing for verification and approval and send us a STEP file when placing an order.

Injection molding profiles

Thanks to the production of individual injection moulds by our own toolmaking department, a large number of other customer-specific profile shapes are available. The profile form can be freely designed within the scope of our production possibilities to suit the respective goods to be transported and the purpose of transport. A fast availability is guaranteed.

Profiles with sprue parts

For special functional features, profiles with enclosed parts can be produced. To shape enclosed parts (made of steel, aluminium, etc.), it is important to ensure that appropriate undercuts are formed. Note: The orderer must provide a sufficient number of sprue parts, whereby approx. 5% excess quantity for sample production must be taken into account.

Download data sheet

Choice of Standard profiles

Flights from existing moulds