Flexible jaw-type and bolt couplings compensate for non-uniform rotary movements. The use of torsionally flexible couplings reduces vibrations or impacts from one shaft to the other. They thereby guarantee power transmission whilst damping torsional vibrations and absorb shocks produced by the uneven operation of certain power machines.

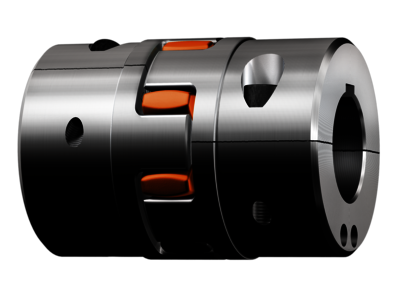

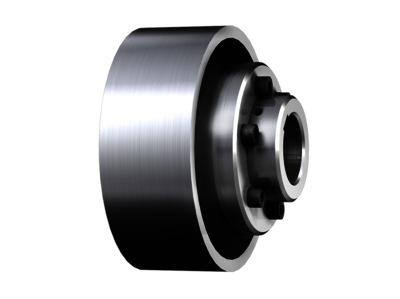

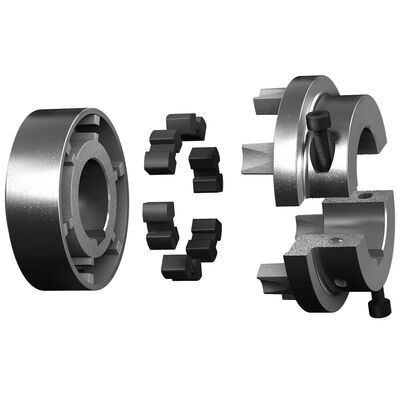

ROTEX®

ROTEX® couplings are characterised by their small dimensions, low weight and low mass moments of inertia yet transmit high torques. They are torsionally flexible and transmit the torque in a positive-fit manner. The precise machining of these couplings has a positive impact on their running quality and also improves the service life of the coupling. Vibrations and shocks are effectively damped and absorbed.

The two congruent coupling halves with concave claws on the inside are peripherally offset in relation to one another by half a pitch. In addition, they are design so as to enable an involute spider to be inserted. The teeth of the spider are crowned to avoid edge pressure if the shafts are misaligned.

ROTEX® couplings are capable of compensating for axial, radial and angular displacements of the connected shafts. The material of the T-PUR® coupling material is available in three degrees of hardness. Unlike other flexible couplings, the intermediate members of which are subject to bending stresses, the flexible teeth of ROTEX® couplings are only subjected to pressure. This means that the individual teeth can accept considerably higher loads.

Properties:

- Flexibly vibration-damping

- Axial plug-in, simple to assemble

- Fail-safe

- Torques up to 35,000 Nm

- Maintenance-free, simple visual inspection

- Teeth material: T-PUR®

Please refer to the respective data sheet for more detailed properties of the individual couplings.

Standard

The ROTEX® Standard coupling is a jaw-type coupling for the damping of torsional vibrations in power transmission. They are designed to be axial plug-in and are characterised by their ease of assembly and maintenance-free design. The standard spiders used are made of high temperature-resistant T-PUR® with an operating range from -50° C to +120 °C with temperature peaks up to +150° C. The couplings have spline toothings according to DIN and SAE and have imperial and taper bores.

Download data sheet

ROTEX® aluminium cast powdermaterial

ROTEX® clamping hubs

ROTEX® Type Hubs

ROTEX® Inch bores and taper bores

ROTEX® Spiders

ROTEX® cylindrical bores and spline bores

ROTEX® clamping ring hubs

ROTEX® taper clamping sleeve

ROTEX® FNN

Steel with KTL coating, stainless steel

The ROTEX® Standard steelwith KTL coating coupling is a jaw-type coupling for the damping of torsional vibrations in force transmission. The hub is pre-bored and coated available ex-stock. It features corrosions protection class according to DIN EN ISO 12944: min. C4, heavy – long and includes the product range ROTEX® 19 – 125.

This ROTEX® Standard coupling is coated by cathodic dip-paint coating. The hub base is made of steel.

The ROTEX® Standard coupling is also available in stainless steel.

Download data sheets

ROTEX® standard stainless steel

ROTEX® CDP coating

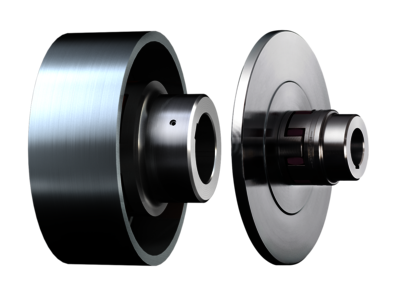

AFN and BFN

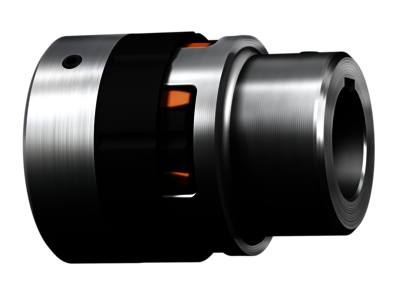

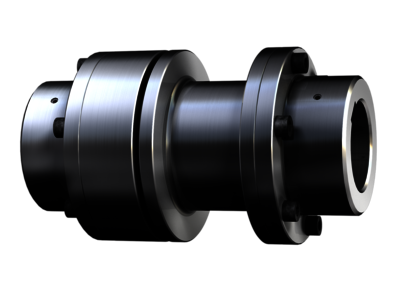

The ROTEX® AFN is a double flange design of coupling designed for heavy machinery. The spider can be replaced when the coupling is installed without the need to remove the driving or driven machine. The flange hub 4N is made of steel, while the driving flange 3Na is made of GGG.

The ROTEX® BFN is a coupling with a flange design suitable for use with heavy machinery. It is characterised by its low mass inertia and features a flange / shaft connection. The flange hub 4N is made of steel, while the driving flange 3Na is made of GGG-40 (nodular iron).

Download data sheets

ROTEX® AFN BFN

ROTEX® AFN SB

A-H

The ROTEX® A-H coupling can be assembled using only four screws. It features steel hubs and is radially assembled. The driving and driven side need to be moved to replace the spider. The ROTEX® A-H is a coupling with a positive-locking and frictionally engaged hub connection.

Download data sheets

ROTEX® A-H

S-H

The ROTEX® S-H coupling is made of grey cast iron. It is characterised by ease of assembly/disassembly with only four screws and both halves of the hubs are centred through the fracture surface.

There is no need to displace the power packs for assembly and the spider can also be replaced without displacing the driving and driven side. The ROTEX® S-H coupling is particularly suitable for use in confined spaces.

Download data sheets

ROTEX® S-H

SP GN and EN

ROTEX® GN and EN couplings have a cam geometry made of conductive and high-strength plastic. The couplings are maintenance-free in hazardous areas, fail-safe and non-sparking.

The hub base is made of steel, aluminium or other metal materials. ROTEX® GN and EN couplings are available with a double-cardanic design for high shaft displacement with low restoring forces.

Download data sheets

ROTEX® SP GN and EN

SP ZS-DKM-C

ROTEX® GSP ZS-DKM-C couplings have a cam geometry made of conductive and highstrength plastic. The coupling is maintenance-free in hazardous areas, fail-safe and nonsparking. The hub base is made of steel, aluminium or other metal materials.

ROTEX® SP ZS-DKM-C couplings are characterised by their ease of assembly/disassembly with only four screws and can be extended up to a shaft distance of 250 mm by means of standard spacers. Thanks to its double-cardanic design, it compensates for large shaft displacements, thus increasing the overall service life of all adjacent components by means of its low restoring forces.

Its suitability for use in hazardous locations is confirmed in accordance with EU Standard 94/9/EG (type 7.6 designated as being ex-stock, type 7.5 half-shell clamping hub without feather keyway according to category 3).

Download data sheets

ROTEX® SP ZS-DKM-C

ZS-DKM-H

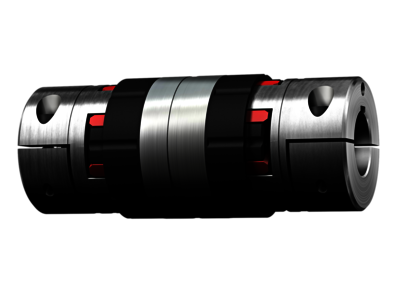

The ROTEX® ZS-DKM-H is a double cardanic jaw-type coupling suitable for high shaft displacements. It features good damping properties, thanks to the double arrangement of spiders. The spacers are adjusted to the drop-out centre lengths of standard pumps.

The ROTEX® ZS-DKM-H coupling is suitable for larger radial displacement resulting from heat expansion. The coupling is assembled using only four screws.

Download data sheets

ROTEX® ZS-DKM-H

DKM

The ROTEX® DKM is a double cardanic jaw-type coupling suitable for high shaft displacements. It features good damping properties, thanks to the double arrangement of spiders and also boasts quiet running due to its lower imbalance with extreme displacements. The ROTEX® DKM coupling has low restoring forces.

Download data sheets

ROTEX® DKM

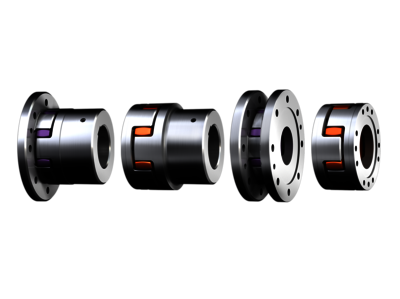

CF, CFN, DF and DFN

The ROTEX® CF is a coupling with a flange design suitable for use with heavy machinery. It has a flange/shaft connection and consists of a driving flange 3b in GGG-40 (nodular iron). It has a particularly short installation length. Customer-specific connection flanges are available on request.

The ROTEX® CFN is a coupling with a flange design suitable for use with heavy machinery. It has a flange/shaft connection and consists of a driving flange 3b in GGG-40 (nodular iron). Its compact external dimensions are a unique feature. Customer-specific connection flanges are available on request.

The ROTEX® DF is a double flange design of coupling designed for heavy machinery. Radial assembly is possible without the removal of other drive components. The flange is made of 3b in GGG-40 (nodular iron). Customer-specific connection flanges are available on request.

The ROTEX® DFN is a double flange design of coupling designed for heavy machinery. It is suitable for the connection of driving and driven machines; radial assembly is possible without the removal of other components. The flange is made of 3b in GGG-40 (nodular iron). Its compact external dimensions are a unique feature.

Download data sheets

ROTEX® CF

ROTEX® CFN

ROTEX® DF

ROTEX® DFN

ZR

BTAN and SBAN

The ROTEX® BTAN is a coupling with brake drum suitable for the installation of external drum brakes. Each types of coupling can be combined with different sizes of brake drum, although the maximum brake torque should not exceed the maximum torque of the coupling. The ROTEX® BATN complies with DIN 15431/15435.

The ROTEX® SBAN is a jaw-type coupling with a disk for brake callipers. Each type of coupling can be combined with different brake disk sizes, although the maximum brake torque should not exceed the maximum torque of the coupling. The brake disk must be fixed to the hub shoulder 1Nd with the ROTEX® SBAN.

Download data sheets

ROTEX® BATN

ROTEX® SBAN

SD

The ROTEX® SD is a shiftable coupling, with which the driving and driven machinery can be engaged and disengaged with the machinery at a standstill.

The shifting hub of the ROTEX® SD can be combined with a slip ring and shift linkage, with pre-bored hubs being set to the required shifting force. The complete shifting device of the coupling consists of a red bronze slip ring, shift fork, shifting shaft, shifting lever and eye type bearing.

Download data sheets

ROTEX® SD

POLY-NORM®

The POLY-NORM® coupling is a torsionally flexible, shear-type shaft coupling, which stands out in particular on account of its short design. It can be used in almost all sectors of mechanical engineering and the pump industry. It is assembled by axially plugging the hubs into each other and impresses with its ease of assembly and maintenance-free design.

This coupling consists of two congruent hubs, which have alternate nubs and pockets arranged on the front side around the circumference. They are blindly plugged into each other, axially displaced by half a nub pitch. The elastomer ring transmits the torque, in a space-saving manner, solely by compression of the elastomer, half in each hub of the coupling.

Properties:

- Axial plug-in, simple to assemble

- Maintenance-free

- Fail-safe

- Short design: minimal shaft spacing dimension

- NBR spider, operating range -30° C to +80° C, temperature peaks up to +120° C

- Torques up to 67,000 Nm

Please refer to the respective data sheet for more detailed properties of the individual couplings.

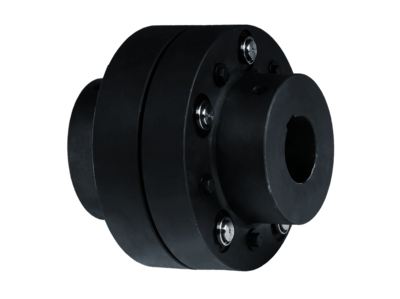

POLY-NORM® AR

The POLY-NORM® AR is a 2-part shaft coupling for torque transmission with damping of torsional vibrations. This is a short design of coupling which has a minimal shaft spacing dimension.

POLY-NORM® AR is axial plug-in for ease of assembly and maintenance-free. It is used throughout the entire field of mechanical engineering.

Download data sheets

POLY-NORM® AR

POLY-NORM® ADR

The POLY-NORM® ADR is a 3-part shaft coupling for torque transmission with damping of torsional vibrations. This is a short design of coupling which has a minimal shaft spacing dimension.

POLY-NORM® ADR is axial plug-in for ease of assembly and maintenance-free. The elastomer spider can be replaced when installed. It is used throughout the entire field of mechanical engineering.

Download data sheets

POLY-NORM® ADR

POLY-NORM® AZR standard coupling for dismounting

The POLY-NORM® AZR standard coupling for dismounting is an intermediate flange coupling for torque transmission with damping of torsional vibrations. The centre piece is available in standard lengths for radial assemblies.

The POLY-NORM® AZR standard coupling for dismounting is axial plug-in for ease of assembly and maintenance-free. It is primarily used in the pump industry and in compressors.

Download data sheets

POLY-NORM® AZR standard coupling for dismounting

POLY-NORM® ADR-BTA

The POLY-NORM® ADR-BTA is used as a stop brake for brake drums. The elastomer spider can be replaced when installed.

The POLY-NORM® ADR-BTA is axial plug-in for ease of assembly and maintenance-free. It is also characterised by its small shaft spacing dimension. This coupling is suitable for torques of from 40 to 5,500 Nm.

Download data sheets

POLY-NORM® ADR-BTA

POLY-NORM® ADR-SBA

The POLY-NORM® ADR-SBA is used as a stop brake for brake callipers. The elastomer spider can be replaced when installed.

The POLY-NORM® ADR-SBA is axial plug-in for ease of assembly and maintenance-free. It is also characterised by its small shaft spacing dimension. This coupling is suitable for torques of from 40 to 5,500 Nm.

Download data sheets

POLY-NORM® ADR-SBA

REVOLEX®

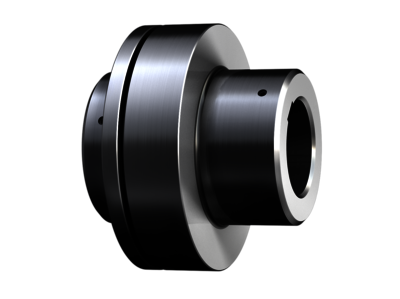

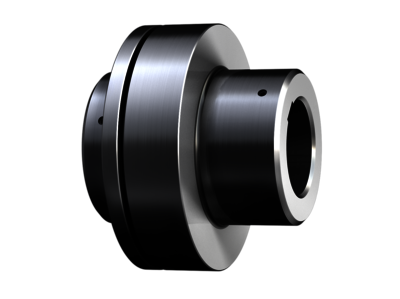

The REVOLEX® coupling is a torsionally flexible bolt coupling without fail-safe device, which stands out in particular on account of its short design. It is assembled by axially plugging the hubs into each other and impresses with its ease of assembly and maintenance-free design.

The REVOLEX® coupling makes it possible to dismantle the elastomer rings including bolts when the coupling is installed. This coupling is made of two hubs that are identical in construction, on the outer pitch circle of which the bolts and pocket holes alternate. The torque is transmitted via the steel bolts with their tapered elastomer rings and the corresponding bore in the bush hub. The REVOLEX® coupling compensates for all kinds of shaft misalignments and reliably transmits the torque.

Properties:

- Fail-safe

- Vibration-damping

- Axial plug-in, simple to assemble

- Maintenance-free

- Short design: minimal shaft spacing dimension

- Torques from 3,800 to 1,220,000 Nm

- Chloroprene-rubber (CR) elastomers

- Elastomer operating range from -30° C to +80° C and short-term max. +120° C

- Easy of disassembly of the complete bolt without major effort

Please refer to the respective data sheet for more detailed properties of the individual couplings.

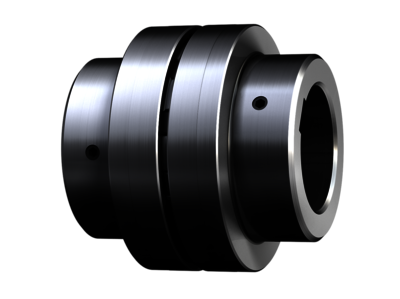

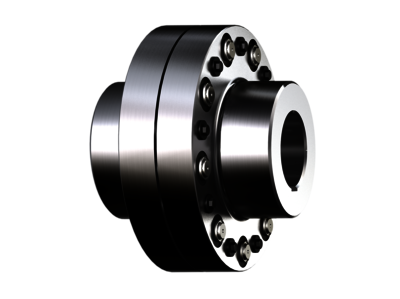

KX-D

The REVOLEX® KX-D grey cast iron is a torsionally flexible bolt coupling. This coupling has a short design, is maintenance-free and has bolts that are radially mountable/removable.

The hub of the REVOLEX® KX-D is made of grey cast iron (ENJ 123456), the surface of which is protected (phosphated). The elastomer rings complete with bolts can be dismantled with ease when fitted. This coupling is available in 14 sizes for torques from 8,650 to 400,000 Nm.

Download data sheets

REVOLEX® KX-D

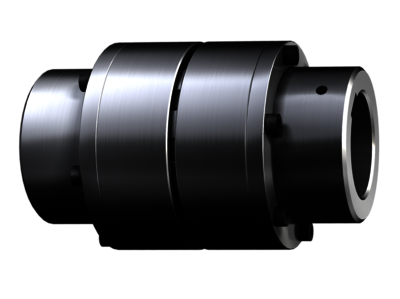

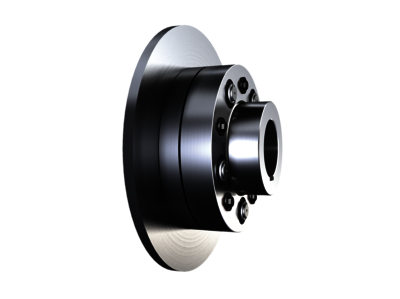

KX-D SB

The REVOLEX® KX-D SB is a torsionally flexible bolt coupling with a brake disc. This coupling has a short design, is maintenance-free and has bolts that are radially mountable/removable. The elastomer rings complete with bolts can be dismantled with ease when fitted. This coupling is available in various sizes for torques up to 92,000 Nm.

Download data sheets

REVOLEX® KX-D SB

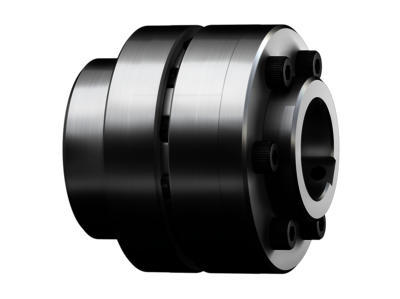

KX-D Steel

The REVOLEX® KX-D steel is a torsionally flexible bolt coupling. This coupling has a short design, is maintenance-free and has bolts that are radially mountable/removable. The hub of the REVOLEX® KX-D is made of steel for higher loads and speeds. The elastomer rings complete with bolts can be dismantled with ease when fitted. This coupling is available in various sizes for torques from 3,800 to 1,220,000 Nm.

Download data sheets

REVOLEX® KX-D Stahl

ROFLEX® puncture-proof shaft couplings

The ROFLEX® shaft coupling is available in versions N and SH. Due to its compact design, it is suitable for use in confined spaces.

The ATEX approval confirms use in potentially explosive areas. It also has EAC approval.

ROFLEX® N

Short standard version

The puncture-proof shaft coupling ROFLEX® N is a short, torsionally flexible 2-part shaft coupling according to DIN 740 for torsional vibration-damping power transmission.

The use of gray cast iron makes the standard version of the ROFLEX® N particularly inexpensive. It reliably transmits torques of up to 5,000 Nm.

During assembly, the hubs are pushed onto the shaft and secured axially using grub screws.

In order to be used in general mechanical engineering and the pump industry, it has ATEX approval and the EAC certificate. The type test certificate is attached to the assembly instructions. They can be found under the “Service” menu item.

- 2-part shaft coupling (pump coupling) for torsional vibration-damping power transmission

- inexpensive standard version

- Axially pluggable, easy to install

- maintenance-free

- short construction: small shaft spacing

Download data sheets

ROFLEX® N

ROFLEX® SH

Shaft coupling with elastomer packages that can be replaced when installed

The puncture-proof, torsionally elastic shaft coupling ROFLEX® SH Split is a 3-part, short shaft coupling for torsional vibration-damping power transmission.

It is an elastomer coupling with fracture-split hubs (SH SPLIT).

This design of the ROFLEX® SH is also known as a clamping coupling, half-shell coupling, coupling with split hubs or elastomer coupling with split clamping hub.

Due to the split hubs, it can be installed and removed radially without having to move the adjacent units. To ensure that the drive is not damaged, a direction of rotation check must be carried out before each electric motor is put into operation. This is easily possible with the ROFLEX® SH and can be implemented on site at the construction site.

- 3-part shaft coupling for torsional vibration-damping power transmission

- Axially pluggable, easy to install

- Easy assembly/disassembly using four screws

- short construction: small shaft spacing

- Elastomer sprocket can be changed when installed

Download data sheets

ROFLEX® SH

POLY®

The POLY® coupling is a torsionally flexible shaft coupling, which stands out on account of its outstanding vibration compensation. It is assembled by axially plugging the hubs into each other and impresses with its ease of assembly and maintenance-free design.

The unique feature of POLY® couplings are the flexible elements (packets) in both coupling halves, thanks to which it is non-fail-safe and interrupts power transmission in the event of an overload or wear.

This POLY® coupling consists of two hubs, which have nubs and pockets arranged on the front side around the circumference. They are assembled to each other by axial blind plug-in. The individual elastomer elements in both coupling hubs are clamped precisely into the gaps and transmit the torque with a very compact design.

Properties:

- For torsional vibration-reducing power transmission

- Axial plug-in, simple to assemble

- Maintenance-free

- Non-fail-safe, with torsional and bending flexibility

- Elastomer operating range from -30° C to +80° C, short-term to +120° C

Please refer to the respective data sheet for more detailed properties of the individual couplings.

POLY® PKA

The POLY® PKA is a torsionally flexible non-fail-safe shaft coupling. It is designed to be axial plug-in and impresses with its outstanding vibration compensation. The centre piece is available in standard lengths for radial assemblies. The elastomer elements can easily be replaced when installed. Fields of application of POLY® PKA couplings include the pump industry and compressor technology.

Download data sheets

POLY® PKA

POLY® PKD

The POLY® PKD is a torsionally flexible non-fail-safe shaft coupling. It is designed to be axial plug-in and impresses with its outstanding vibration compensation. The elastomer elements can easily be replaced when installed. The POLY® PKD coupling is a 3-part short design with a short shaft distance dimension. It is used in the field of general mechanical engineering.

Download data sheets

POLY® PKD

POLY® PKZ

The POLY® PKZ is a torsionally flexible non-fail-safe shaft coupling. It is designed to be axial plug-in and impresses with its outstanding vibration compensation. The number of elastomer elements can be increased on request. The POLY® PKD coupling is a 2-part short design with a short shaft distance dimension. It is used in the field of general mechanical engineering.

Download data sheets

POLY® PKZ