Thanks to a large number of coating types and timing belts with standard and special profiles, the timing belts can be designed individually and as required for your application.

Our range also includes standard vacuum timing belts for which customer-specific requirements can also be realized. These coated timing belts with milled suction pockets are used in vacuum transport technology. They are preferably manufactured with tension member-free zones in order to be able to drill holes to extract the air. Suction channels are used on the tooth side, where the tooth side is milled out in longitudinal direction according to the hole size.

BRECOroll

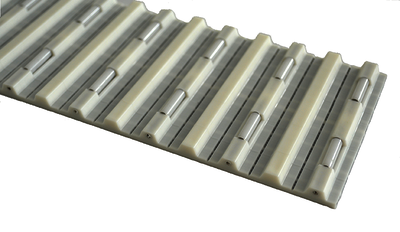

With the new BRECOroll roller belt, friction in material transport systems can be minimized. Thanks to integrated rollers in the teeth of this polyurethane timing belt, this product is ideally suited for material and transport technology. Frequently, timing belts used for material transport are quite long and are guided by means of a lateral support rail that absorbs the weight forces of belts and transported workpieces. The resulting friction has to be overcome by the use of drive power and generates heat as an undesirable by-product, which not only lowers the strength of the belt but also reduces its service life. The new BRECOroll is characterized by rollers in the belt teeth, which replace the resulting sliding friction with rolling friction. Thus, both the drive power and the self-heat can be reduced and the belt service life increased.

The BRECOroll requires a belt tooth with 20mm pitch, has a T-profile and is only available in pitch T20 in 100mm width..

Download data sheet

T20

BRECOvacuum

If products such as foils, glass panes, paper or similar have to be transported by means of toothed belts, this is usually done by a negative pressure. Often the components and timing belts used for this purpose are special custom-made products that are individually implemented for the respective end customer. The new BRECOvacuum represents an alternative for these cases. The newly developed timing belt-pulley system combines toothing, suction channels and sealing strips in one timing belt. Thanks to the precisely matched components, the individual parts of the timing belt pulleys fit exactly to the suction area on the timing belt.

The BRECOvacuum is available in the AT10 version in widths of 50 mm and 75 mm.

Download data sheet

AT10

Coatings

The timing belts can be coated with a wide variety of materials and thus be used for various tasks in transport technology. The appropriate coating is selected depending on the properties of the respective transport goods and the required adhesion.