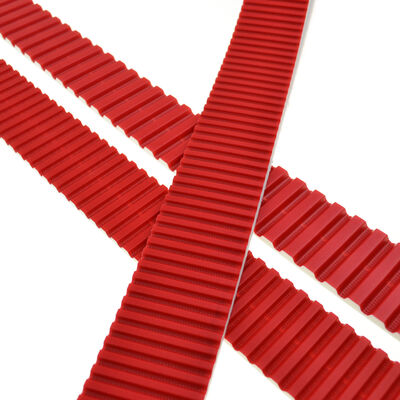

Endless PU timing belts are made of wear-resistant polyurethane and high-tensile steel cord tension members. The unique properties of polyurethane timing belts include their outstanding performance potential, enormous strength and dimensional precision. The timing belts are temperature-resistant at ambient temperatures of -30°C to +80°C, their load capacity, even at high speeds, and uniform load distribution during power transmission enables them to have a diverse range of uses in drive technology. The extensive range of different polyurethane compounds also permits their use in specialist areas (e.g. in the food industry).

Polyurethane timing belts are offered in a range of high-performance profiles.

Properties:

Mechanical

- Positive-fit, synchronising

- Constant length, no post-elongation

- Low noise

- Wear-resistant

- Low maintenance

- Highly flexible

- Positional and angular precision

- Fatigue-resistant, low-stretch steel cord tension member

- Max. belt speed up to 80 ms-1

- Small build dimensions

- Favourable power-to-weight ratios

- Low pre-tension

- Low bearing load

- Permits large centre distances

- Permits large transmission ratios

- High efficiency, max. 98 %

Chemical

- Hydrolysis-stabilised

- Resistant to ageing

- Temperature-resistant from -30° C to +80° C,

- Resistant to tropical climates

- Resistant to simple oils, fats and petrol

- Conditionally resistant to acids and lyes

Please refer to the respective data sheet for more detailed properties of the individual timing belts.

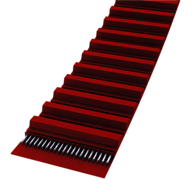

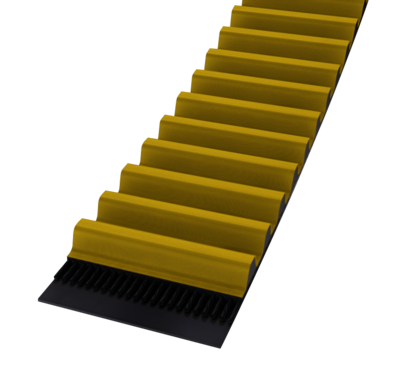

AT

Further development of the T profile resulted in the AT profile. This timing belt profile is characterised by its higher tooth shear strength resulting from the larger tooth volume and reinforced tension members.

Benefits:

- Favourable tooth mesh

- Strengthened tension members for constant pitch

- Up to 50% improved performance over the T profile

- Precise transmission of movement combined with synchronous pulleys with reduced or zero backlash

- Reduced meshing impacts or shocks

- Compact mass ratio and installed dimensions

(also available in the GEN III version)

Breco BRECOFLEX®

BRECOFLEX® timing belts are produced in endless lengths without continuous tensionmembers and feature a tension member coiled in a thread pattern. The timing belts are available as Standard and StandardPlus.

The endless timing belts (Standard) are used on all drives designed for high performance and are capable of withstanding continuous or also start-brake-operation. Speed range up to 10,000 rpm.

The new BRECOFLEX® StandardPlus timing belt generation was developed for use in high-precision positioning applications. The use of bifilar tension member coiling significantly reduces run-off tendency of the timing belts, as it prevents the build-up of lateral forces during running.

Download data sheets

AT3

AT5

AT10

ATS15

AT20

Breco BRECOFLEXmove

The BRECOFLEXmove is a timing belt specifically designed for high-performance drives and traction drives with a particularly high stiffness requirement. A newly developed steel cord tension member increases belt stiffness and tear-resistance, making transmission of stronger forces possible. The tooth flank geometry has been optimised through the Finite Element Method (FEM). This leads to an optimisation of the contact pressure distribution and reduces the work of friction between the timing belts and tooth washers, thus minimising wear. In addition, a friction-optimised laminate coating is applied to the tooth side.

Selecting a narrower BRECOmove timing belt as an alternative to a standard timing belt makes a more compact drive design possible. Depending on the circumferential forces actually to be transmitted in the application, it is advisable to use a material with higher strength or an additional surface coating for the toothed pulleys.

Download data sheets

AT8 move

AT10 move

AT15 move

Conti® SYNCHROFLEX

CONTI® SYNCHROFLEX timing belts are available as Standard and GEN III versions.

The high-performance standard version:

A combination of high-strength steel cord tension members and wear-resistant polyurethane ensures dimensional precision and resistance.

Product properties:

- Constant length, no post-elongation

- Good dimensional precision

- High torque transmission

- Smooth-running

- Maintenance-free

- No belt lubrication

- Good resistance to mechanical and chemical influences.

Further development of GEN III up to 25% higher power transmission

- - Fper to max. 45% due to more closely wound cords

- Bifilar tension members and balanced S- and Z-stroke design for significantly reduced run-off tendency/optimised directional stability

- Reduced flange friction

- Lower running noise with narrower belt width and identical performance

- Fspec +25 %

- Longer service life

- Longitudinal force distribution on up to 30% more load-bearing teeth

- Operation up to +100° C

Download data sheets

AT 3 GEN III

AT 3

AT 5 GEN III

AT 5

AT 10 GEN III

AT 10

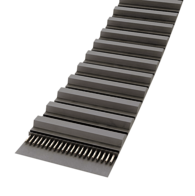

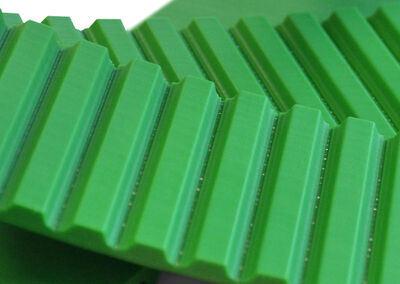

ATP

Further increased performance, noise reduction and extended service life led to the development of the ATP timing belt in 1993.

At the time, the focus was on the optimum tooth form. The basic concept of the new ATP profile provides for the division of the trapezoidal tooth into two individual load-bearing teeth.

Up to 60% increased performance, running noise reduction of up to 10 dB(A) and a longer service life are achieved by the following factors:

- 70% larger load-bearing tooth surface area

- Uniform tension distribution

- Improved power dispersion

- Reduced polygon effect

- Narrower construction width

- Optimised tooth mesh

(also available in the GEN III version)

Breco BRECOFLEX®

BRECOFLEX® timing belts are characterised by their production in endless lengths without continuous tension members and feature a tension member coiled in a thread pattern. Suitable for universal use in drive technology, the timing belts are suitable for all applications up to 10,000 rpm. The Standard and StandardPlus versions are suitable for continuous and start-brake operation.

Thanks to the further development of the Standard BRECOFLEX® timing belt, customers can now also opt for the StandardPlus BRECOFLEX® timing belt, which is primarily designed for use in high-precision positioning applications.

Download data sheets

Conti® SYNCHROFLEX

Dimensionally stable and extremely durable CONTI® SYNCHROFLEX® timing belts are available as Standard and GEN III versions.

The Standard version:

High-strength steel cord tension members combined with abrasion-resistant polyurethane guarantee the following product features:

- Constant length

- No post-elongation

- Good dimensional precision

- Suitable for high torque transmission

- Low-noise running

- Maintenance-free

- No belt lubrication needed

- Resistant to mechanical and chemical influences

The further development of the GEN III generation of timing belts is characterised primarily by up to 25% higher power transmission.

- Fper up to max. 45%, thanks to more closely wound cords

- Bifilar tension members and balanced S- and Z-stroke design for significantly reduced runoff tendency and optimised directional stability

- Reduced flange friction

- Minimised running noises with narrower belt width and identical performance

- Fspec +25 %

- Longer service life

- Longitudinal force distribution on up to 30% more load-bearing teeth

- Operation up to +100° C

Download data sheets

ATP 10 GEN III

ATP 10

ATP 15 GEN III

ATP 15

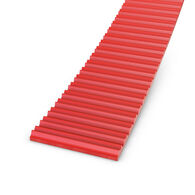

T

The trapezoidal Standard T profile is classified according to DIN 7721 and is regarded as a classic amongst timing belts. Its preferred areas of applications include:

- Standard drive applications

- Drive applications with double toothed belt

- Applications with high bending stresses

- Loads “with contraflexure”

T profile with DL design

Both sides of the belt are toothed on DL timing belts. These timing belts are used in drive and transport engineering. Multi-shaft drives with different rotational directions of individual shafts can be achieved with this timing belt. Both toothed sides can be fully loaded.

Breco BRECOFLEX®

BRECOFLEX® timing belts are manufactured in endless lengths without continuous tension members and feature a tension member coiled in a thread pattern. Suitable for universal use in drive technology, the Standard T profile is suitable for all drives up to 10,000 rpm. The Standard and StandardPlus versions are suitable for continuous operation and also start-brake operation.

Conti® SYNCHROFLEX

The CONTI® SYNCHROFLEX with Standard T profile features a metric pitch and trapezoidal cogging.

- Singe-sided cogging

- Aramide tension member

- Polyurethane special materials on request

- Antistatic, mono-coloured, mechanically reworked

Dimensionally stable and extremely durable CONTI® SYNCHROFLEX timing belts are only available in the Standard version.

Imperial

PU timing belts, manufactured in endless lengths with imperial pitch according to DIN/ISO 5296, are available in the following sizes:

- M (MXL) = 2.032 mm

- L = 9.525 mm

- XL = 5.080 mm

- H = 12.700 mm

- XH = 22.225 mm

Their preferred use lies in applications with imperial units.

Breco BRECOFLEX®

BRECOFLEX® timing belts are manufactured in endless lengths without continuous tension members and feature a tension member coiled in a thread pattern. They are suitable for all applications in drive technology up to 10,000 rpm and are available in different imperial sizes.

DR version – reinforced belt backing

DL version – the standard version is double toothed; the compound polyurethane and high-strength steel cord tension member structure can be fully loaded on both sides.

CONTI® SYNCHROFLEX

The CONTI® SYNCHROFLEX imperial timing belt has standard trapezoidal cogging according to DIN/ISO 5296 with mini pitch (2.032 mm = 0.08 inch). This timing belt is available in size M (MXL) in standard polyurethane with steel cord tension members.

- Singe-sided cogging

- Aramide tension member

- Polyurethane special materials on request

- Antistatic, mono-coloured, mechanically reworked

Download data sheets

M

Special Profiles

The CONTI® SYNCHROFLEX, PU timing belt manufactured in endless lengths is available with the special profile K.

K:

Serrated profile with metric pitch.

Preferred applications: Fine mechanical technology requiring small dimensions

Available versions:

• Singe-sided cogging

• Aramide tension member

• Polyurethane special materials on request

• Antistatic, mono-coloured, mechanically reworked

Download data sheets

K

Self-tracking timing belts

BRECOFLEX® timing belts are manufactured in an endless length and feature a tension member coiled in a thread pattern. The self-tracking profiles are suitable for use with drives of all kinds and can be used within a speed range of up to 10,000 rpm.

Continuous operation and start-brake operation are possible for the Standard and StandardPlusversions.

- DR version – timing belt with reinforced belt backing

- DL version – the standard version is double toothed; the compound polyurethane and high-strength steel cord tension member structure can be fully loaded on both sides.

Download data sheets

BAT10

BAT15

BATK10

BATK15

SFAT10

SFAT15

SFAT20

ATK5K6

ATK10K6

ATK10K6-DL

ATK10K6-DR

TK5K6

TK10K6

TK10K13

CTD

High-performance timing belt for all extreme applications with the highest torque demands to the replacement of chain drives.

The newly developed CTD profile offers harmonic tooth meshing at high speeds and thus ultra-smooth running. It also provides excellent protection against ratcheting at high torques. This high-performance timing belt satisfies all requirements whether for new designs or as a replacement in existing systems. Available with a CTD C8M pitch. Other pitches, length and width ranges on request.

CONTI® SYNCHROCHAIN CARBON

Higher power transmission, longer service life, no initial tension losses, but in addition 50% less elongation than with aramide, thanks to the use of carbon. Its newly developed carbon tension member secures the CONTI® SYNCHROCHAIN CARBON a place in the elite group of the world’s highest-performance timing belts.

The CONTI® SYNCHROCHAIN CARBON can transmit up to 5 times more power than conventional timing belts with the same overall width. This means that the belt can be significantly narrower and the overall width can be reduced by 80% to transmit the same power. This means the overall systemcosts are significantly reduced by using the CONTI® SYNCHROCHAIN CARBON.

Properties:

- Temperature-resistant, depending on the application

- from -40°C to +80°C

- Suitable for tropical climates

- Resistant to ageing and ozone

- Resistant to contraflexure

- Resistant to simple oils, fats and petrol

- Conditionally resistant to acids and lyes

- Silicone-free raw materials and production

- Maintenance-free

- Belt speeds up to 40 m/s

- Increased power output

- Longitudinally stable throughout its lifetime

Download data sheets

Timing belts made with renewable raw materials

BRECOgreen / BRECOFLEXgreen

This name stands for a range of timing belts that will not only benefit the customers who use them but also do their bit to help preserve the planet in general. With the BRECOgreen and BRECOFLEXgreen ranges of timing belts, we are the first belt manufacturer to take a step beyond merely creating another product. We have used the word “green” in the names of these products to highlight the optimised use of materials, with renewable materials making up 37%.

At BRECO, it is particularly important to us that these materials are not taken from the human food chain. Since the load-bearing capacity and service life of BRECOgreen/BRECOFLEXgreen belts match those of belts manufactured from oilbased thermoplastic polyurethane, we can absolutely guarantee their fulloperational reliability.

Long-term market studies have shown that even small steps in the right direction are important. They encourage others to follow suit and help to develop new materials and techniques that can be transferred to other areas. We continue to invest all our energy in innovative technology so that we can help to preserve and improve the environment, climate and living conditions.

The “green” material is available for all BRECO and BRECOFLEX types, regardless of their pitch and profile. Please specify the material TPUEC1 in the request.

BRECOgreen

- Offers sustainability through the use of renewable raw materials

- Represents a user-friendly alternative

- Matches the performance and properties of conventional products

- Signals an eco-friendly approach

Download data sheets

BRECOgreen / BRECOFLEXgreen