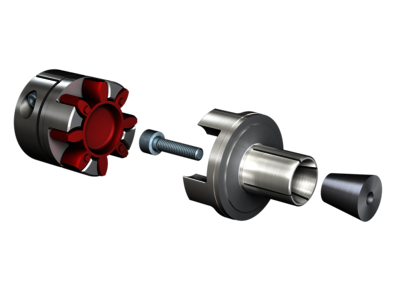

Backlash-free servo couplings transmit the torque with zero backlash even with alternating directions of rotation, i.e. the torque is transmitted from one shaft to another without displacement. This is achieved through the use of a spider.

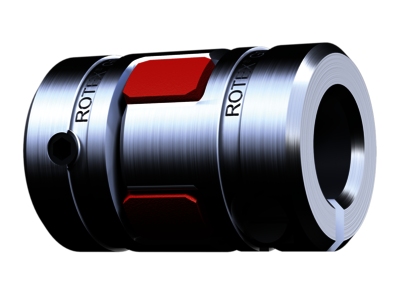

ROTEX® GS

ROTEX® GS are three-part axial plug-in couplings, which are backlash-free under pretension and cannot fail to impress with their backlash-free torque transmission, ideally adapted stiffness and optimum vibration reduction even in critical applications. Its easy-toinstall and production-optimised installation options make the ROTEX® GS a frequently used coupling.

The straight toothing of the pre-tensioned spider results in lower surface pressure and thus greater stiffness of the coupling system. The flexible teeth are radially supported by a web on the inside diameter when absorbing displacement. This prevents too great inward or outward deformation of the ROTEX® GS with excessive acceleration or at high speeds, ensuring its outstanding operation and durability.

Properties:

- Backlash-free, vibration-reducing jaw-type coupling

- Axial plug-in

- Maintenance-free and electrically conductive

- Fail-safe

- Couplings for machine tools, automation, power transmission, medical technology and packaging technology

Please refer to the respective data sheet for more detailed properties of the individual couplings.

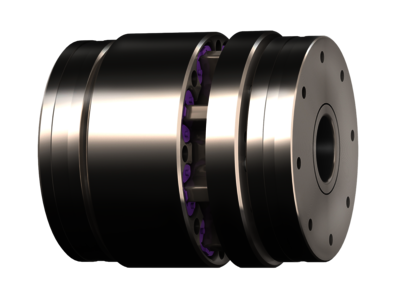

ROTEX® GS HP

The ROTEX® GS HP is a backlash-free and flexible shaft coupling, which reaches circumferential speeds of up to 175 metres per second. Surface pressure is reduced on each individual elastomer due to the number of torque-transmitting elastomer segments, which enables the transmission of high torques with a small coupling outer diameter.

Download data sheets

ROTEX® GS HP

ROTEX® GS Standard models

The ROTEX® GS Standard coupling is a backlash-free, vibration-damping, jaw-type coupling which is axially plug-in. It is characterised by its lack of maintenance and is also electrically isolating. Torques of 0.2 to 5,850 Nm and ambient temperatures of -50° C to +150° C are possible (depending on the sprocket).

Download data sheets

ROTEX® GS

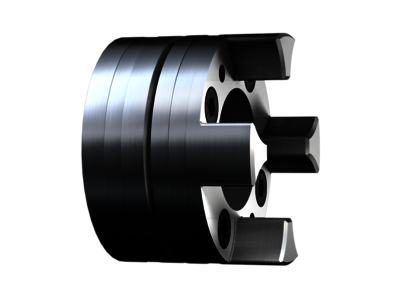

ROTEX® GS Compact

The ROTEX® GS Compact coupling is a compact backlash-free jaw-type coupling. It is up to 1/3 shorter than standard models and is axially slotted. The ROTEX® GS Compact is a short clamping hub design of coupling, which is particularly suitable for use in confined spaces. It is characterised by its good concentric running properties and uniform power transmission on account of its unslotted nub area.

Download data sheets

ROTEX® GS Compact

ROTEX® GS light clamp ring hub

The ROTEX® GS clamping ring hub light is an optimised version of the existing clamping ring hub design and boasts an integral aluminium clamping system. The aluminium hub combined with the aluminium ring produce a low mass moment of inertia. The ROTEX® GS clamping ring hub light can be assembled easily, thanks to its internal clamping screws. It boasts high friction torques and enhanced running smoothness. This coupling is used at up to a circumferential speed of 50 m/s.

Download data sheets

ROTEX® GS light clamp ring hub

ROTEX® GS clamping ring hub steel

The ROTEX® GS clamping ring hub steel is a backlash-free jaw-type coupling which is specifically suitable for use with high shock loads. These clamping ring hubs with hard spiders are used in drives with high torques. The ROTEX® GS clamping ring hub steel has an internal clamping system and is ideal for the transmission of high friction torques to smooth shafts. It impresses with its ease of assembly and very smooth and quiet running properties. This coupling is used at up to a circumferential speed of 40m/s.

Download data sheets

ROTEX® GS steel clamp ring hub

ROTEX® GS P according to DIN 69002

The ROTEX® GS P according to DIN 69002 is a highly precise backlash-free jaw-type coupling, which features an integrated steel clamping system. Thanks to its precise manufacturing, this coupling can be used at very high speeds and circumferential speeds of > 50 m/s. The ROTEX® GS P was developed specifically for stub spindles on multiple spindle heads according to DIN 69002. It is characterised by its ease of assembly and high friction torques.

Download data sheets

ROTEX® GS P according to DIM 69002

ROTEX® GS-P ETP®

The ROTEX® GS-P ETP® is a backlash-free, vibration-damping shaft coupling with integral ETP quick clamping system. This coupling can be quickly assembled and disassembled with only one screw. It is characterised by its extremely good concentricity even after thousands of uses. The ROTEX® GS-P ETP® is suitable for use in accessible locations as the pressure screw is tightened in a radial direction to the shaft.

Download data sheets

ROTEX® GS-P ETP®

ROTEX® GS expansion hub

The ROTEX® GS expansion hub has an integral clamping system for hollow shaft connections. It has a short design and can be quickly assembled. This coupling has a selfcentering clamping connection and can be combined with different hub designs.

Download data sheets

ROTEX® GS expansion hub

ROTEX® GS A-H

The ROTEX® A-H is a coupling with half-shell clamping hubs. This design is ideal for radial assembly and disassembly of the driving or driven side. The ROTEX® GS A-H is assembled

and disassembled with four screws enabling the spider to be removed without displacing the driving and driven side.

Download data sheets

ROTEX® GS A-H

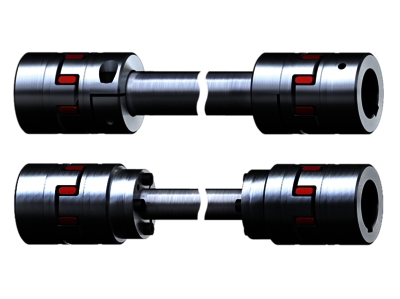

ROTEX® GS DKM

The ROTEX® GS DKM is a double cardanic jaw-type coupling, which is used where high shaft displacements need to be compensated for or shaft distance dimensions overcome.

Download data sheets

ROTEX® GS DKM

ROTEX® GS ZR3

The ROTEX® GS ZR3 is an intermediate shaft coupling with a glued aluminium pipe. It is one of three intermediate shaft couplings that can be used to bridge large shaft distances. The aluminium intermediate pipe is adjusted to meet the customer’s dimensions. The ROTEX® GS ZR3 can be radially assembled due to its separate coupling hubs. The spider can be replaced without displacing the driving and driven side. Up to 4-metre lengths of the ROTEX® GS ZR3 are possible without intermediate bearing, depending on the speed and size.

Download data sheets

ROTEX® GS ZR3

ROTEX® GS ZR1 and ZR2

The ROTEX® GS ZR1 is an intermediate shaft coupling with clamping hubs on the intermediate pipe. It is one of three intermediate shaft couplings that can be used to bridge large shaft distances and is available in sizes 14 to 38. The intermediate spacer parts can be disassembled radially. The clamping hubs on the intermediate pipe can be axially shifted, which permits radial assembly or disassembly without the need to displace the driving and driven side. br>

The ROTEX® GS ZR2 is an intermediate shaft coupling with CLAMPEX clamping elements for higher friction contact. It is one of three intermediate shaft couplings that can be used to bridge large shaft distances and is available in sizes 14 to 65. The clamping sets on the intermediate shaft enable high torques to be transmitted and can be displaced for radial assembly/disassembly.

Download data sheets

ROTEX® GS ZR1

ROTEX® GS ZR2

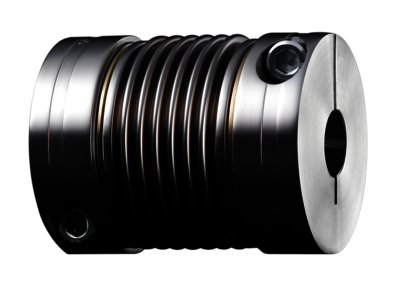

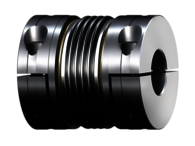

TOOLFLEX®

TOOLFLEX® is a torsionally stiff, flexible metal bellow coupling with a stainless steel bellow and aluminium coupling hubs, which compensates perfectly for axial, radial and angular displacement. Thanks to its geometric shape, the TOOLFLEX® coupling has excellent torsional stiffness and a low mass moment of inertia.

The connection between the bellow and the hub is dependent on its size.

Properties:

- Backlash-free, torsionally stiff metal bellow coupling

- Maintenance-free

- Non-fail-safe

- Ambient temperatures up to 200° C are possible (depending on the size)

- Torques from 0.1 to 600 Nm

- Couplings for drive technology, automation, medical technology, packaging technology and machine tools

Please refer to the respective data sheet for more detailed properties of the individual couplings.

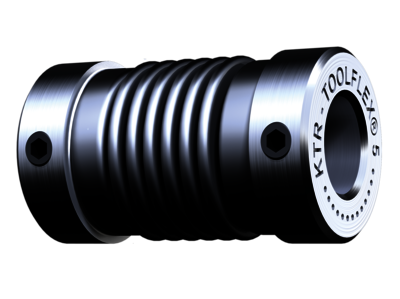

TOOLFLEX ® S

The TOOLFLEX® S coupling is a torsionally stiff flexible metal bellow coupling with a short bellow, which is capable of compensating for axial, radial and angular shaft displacement. It has a hub with a set screw thread for applications with small torques and increased torsional spring stiffness. The TOOLFLEX® S coupling is also available with feather key. It is suitable for torques of 0.1 to 15 Nm and is resistant to the influence of media or critical operating conditions.

Download data sheets

TOOLFLEX® S

TOOLFLEX ® M

The TOOLFLEX® M coupling is a flexible metal bellow coupling, which is capable of compensating for axial, radial and angular shaft displacement. It features a bellow with six shafts for greater displacement capacity and guaranteed torsionally stiff power transmission. The TOOLFLEX® M is suitable for torques of 1 to 600 Nm and can be used at up to +200 °C.

Download data sheets

TOOLFLEX® M

TOOLFLEX ® Mini

The TOOLFLEX® Mini coupling is a flexible mini metal bellow coupling, the metal bellow of which ensures the optimum compensation of axial, radial and angular shaft displacement. It is available in the standard version with a 6-shaft bellow or optionally also with a 4-shaft bellow.

The TOOLFLEX® Mini incorporates hubs with and without feather key, with aluminium hubs being glued to the bellow. It is suitable for torques from 0.1 to 15 Nm and can be used at up to +100 °C.

Download data sheets

TOOLFLEX® Mini

TOOLFLEX ® KN

The TOOLFLEX® KN coupling is a torsionally stiff flexible metal bellow coupling which has an integral clamping system with a tapered clamping ring hub. The metal bellow ensures optimum compensation of axial, radial and angular shaft displacement. It is available either with a 6-layer bellow or a 4-layer bellow. The TOOLFLEX® KN is characterised by a frictionlocking bellow-hub connection and features optimum concentricity due to its symmetrical construction. It is suitable for torques of 35 to 340 Nm.

Download data sheets

TOOLFLEX® KN

TOOLFLEX® PI

The TOOLFLEX® PIcoupling is a torsionally stiff flexible bellow coupling which can be axially plugged in. The metal bellow ensures optimum compensation of axial, radial and angular shaft displacement. It is available either with a short 4-layer bellow or a 6-layer bellow.

Download data sheets

TOOLFLEX® PI

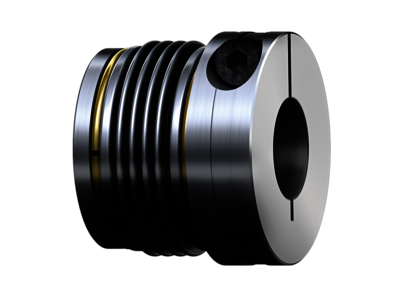

TOOLFLEX ® CF

The TOOLFLEX® CF coupling is a torsionally stiff flexible bellow coupling with an extremely short design, which is maintenance-free. The metal bellow ensures optimum compensation of axial, radial and angular shaft displacement.

Thanks to its welded joint, the TOOLFLEX® CF is suitable for use at high temperatures. It is characterised by its good torsional rigidity and is suitable for torques from 35 to 340 Nm. Apart from a short 4-shaft or 6-shaft bellow, special designs also enable a 1-, 2- or 3-shaft bellow to be produced

Download data sheets

TOOLFLEX® CF

TOOLFLEX ® S-H / M-H

The TOOLFLEX® S-H / M-Hcoupling is a torsionally stiff flexible metal bellow coupling, which can be easily assembled and disassembled thanks to its half-shell design. The metal bellow ensures optimum compensation of axial, radial and angular shaft displacement. It has backlash-free torque transmission and compensates for shaft displacement with low restoring forces.

Download data sheets

TOOLFLEX® S-H / M-H

TOOLFLEX ® ZR

The TOOLFLEX® ZR coupling is a torsionally stiff flexible metal bellow coupling with a variable length of up to 4 m. The metal bellow ensures the optimum compensation of axial, radial and angular shaft displacement. It has excellent torsional stiffness, high bending critical speed and low moments of inertia. The TOOLFLEX® ZR can be simply radially assembled and disassembled.

Download data sheets

TOOLFLEX® ZR

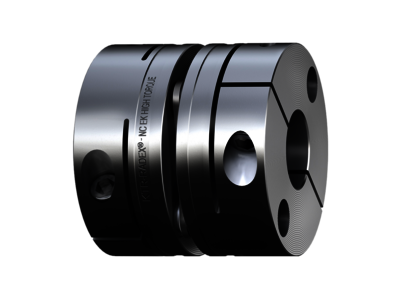

RADEX®-NC

The RADEX®-NC is a servo lamina coupling with torsionally stiff, but soft-bending steel lamina, which reliably compensate for axial, angular and radial shaft displacement. This allmetal coupling can be used at temperatures of up to +200°C and in aggressive ambient conditions. The RADEX®-NC is available as a single cardanic or double cardanic coupling. Typical applications include backlash-free screw gears with small transmission ratios.

Properties:

- Backlash-free, torsionally stiff servo lamina coupling

- Maintenance-free

- Ambient temperatures up to +200° C are possible

- Torques from 2.5 to 300 Nm

- Couplings for automation, drive technology and medical technology

Please refer to the respective data sheet for more detailed properties of the individual couplings.

RADEX®-NC High Torque

The RADEX®-NC High Torque is a backlash-free and torsionally stiff steel lamina coupling, which achieves speeds of up to 27,500 rpm and transmits torques of up to 2,000 Nm. With this lightweight, compact coupling, the connections between the lamina and hubs are designed to be friction-locking and positive-locking, which enables them to be used in servo drives in the higher-performance range. This maintenance-free servo coupling is especially suitable for use in machine tools, measuring and test technology, automation technology and in serve drives.

Download data sheets

RADEX®-NC High Torque

RADEX®-NC EK

The RADEX®-NC EK coupling is a torsionally stiff servo lamina coupling with soft-bending steel lamina, which reliably compensates for axial, angular and radial shaft displacement, can be used at up to +200°C and with aggressive conditions, thanks to its stainless steel design. It has a short design and works on the single-cardanic coupling principle. The RADEX®-NC-EK is optionally available with a feather key.

Download data sheets

RADEX®-NC EK

RADEX®-NC DK

The RADEX®-NC DK coupling is a torsionally stiff servo lamina coupling with soft-bending steel lamina, which reliably compensates for axial, angular and radial shaft displacement, can be used at up to +200°C and with aggressive conditions, thanks to its stainless steel design.

It works on the double-cardanic coupling principle. The RADEX®-NC DK is optionally available with a feather key.

Download data sheets

RADEX®-NC DK

RADEX®-NC miniature coupling

The RADEX®-NC miniature coupling is a torsionally stiff servo lamina coupling with softbending steel lamina, which reliably compensates for axial, angular and radial shaft displacement, can be used at up to +200°C and with aggressive conditions, thanks to its stainless steel design.

It is available as a single cardanic and also double cardanic coupling and can be used at torques of 2.5 to 7.5 Nm. The RADEX®-NC miniature coupling is clean room-certified.

Download data sheets

RADEX®-NC Miniature Coupling

COUNTEX®

The COUNTEX® is a three-part, backlash-free and torsionally rigid coupling, which was developed to meets the demands of measuring and control technology. Its axial plug-in ability combined with the hub geometry results in a coupling system that offers quick fitting and ease of assembly.

The use of high temperature-resistant material for the spacer means that the COUNTEX® encoder coupling can be used at temperatures of up to 160°C with almost constant properties.

Reproducible positions can be achieved, thanks to its good torsional stiffness, at the same time compensating for displacements without any major forces affecting the adjacent components.

Properties:

- Backlash-free, torsionally stiff encoder coupling

- Maintenance-free

- Axial plug-in

- Electrically isolating

- Shaft diameters of up to Ø 14 mm are possible

- Ambient temperatures from -40° C to +160° C are possible

Please refer to the respective data sheet for more detailed properties of the individual couplings.